HENSEL & BLANK toolOpener®

From 500 kilograms to 50 tons

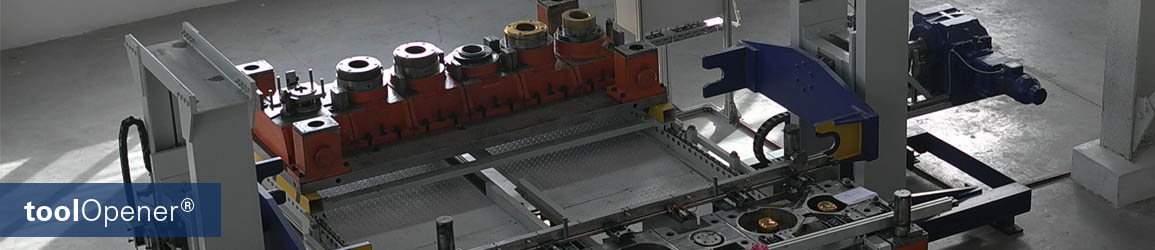

The definitive solution for safe and economic handling of any sized stamping, forming and injection tools

Our company is specialized in handling stamping, forming and injection tools from 500kg to 50t. We developed the toolOpener®, that has been tried and tested multiple times and comes into operation worldwide by now, to counteract the following problems:

- Unsafe handling of tools via crane or forklift with subsequent bad working conditions and high tool costsbecause of cracks or joint flaws

- Poor accessibility increases the error rate of maintenance and replacements with the consequence of high reject rates in production

- Downtimes because of unnecessary replacement and maintenance works inside the press

We offer the Hensel & Blank toolOpener® as a mobile version for smaller and medium-sized tools, as well as the stationary version – optional in conjunction with tool changing systems. These establish the basis of a safe, ergonomic and efficient tool management. An amortisation period within one year is generally achievable.

From fully automated solutions for the moving and opening of different tool types and sizes to basic semiautomatic facilities – anything is possible. Additively through the application of standard components, the storage costs and downtimes will be reduced. Of course remote diagnosis can be performed online.

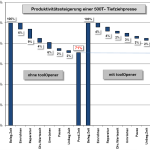

The toolOpener® increases productivity

The toolOpener® increases productivity

The usual losses of 20% to 30% that appear during installment, rebuilding and repair works can be reduced by 10% by our toolOpener®.

toolOpener® up to 2.000 Kilograms

toolOpener® up to 2.000 Kilograms

tO 02.0-S: Stationary tool handling concept to mount stamping and forming tools of different sizes.

[su_expand more_text=”more Information” less_text=”close” height=”0″ text_color=”#0f3060″ link_color=”#fff” more_icon=”icon: cogs” less_icon=”icon: cogs” class=”MehrLesenSm”]

- Vertical movement of the tool table via motor-driven synchronized trapezoidal spindles

- Lifting speed continuously variable. Therefore most accurate fine-tuning works can be done. A dead man’s switch ensures security during the lifting movement.

- A tool table to move tools easily via ball casters

- Automatically immersible safety components prevent the tool’s crash

- 360° Rotating movement of the upper part of the tool through manual worm gear (self-locking) – lockable in zero position

- Mounting the upper part of the tool per spindle driven clamping elements

- A console table is suitable for loading and unloading via crane as well as via tool changeover carriage

[/su_expand]

toolOpener® up to 10 tons

toolOpener® up to 10 tons

tO 10.0-S: Stationary tool handling facility to mount stamping and forming tools of different sizes

[su_expand more_text=”more Information” less_text=”close” height=”0″ text_color=”#0f3060″ link_color=”#fff” more_icon=”icon: cogs” less_icon=”icon: cogs” class=”MehrLesenSm”]

There are 3 positions provided for the tools:

– Placing position upper part of the tool

– Placing and transfer position lower part of the tool

– Opening position

- Loading and undloading via crane as well as via tool changeover carriage

- Hoist unit side stands proceed symmetrically and are hydraulically engined

- Precision guided lifting box engined hydraulically under position control

- 360° turnable cross mounted rotating unit engined by a hydraulic motor

- Control: e.g. Siemens SIMATIC S7 in conjunction with a SIMATIC Touch-Panel

[/su_expand]

toolOpener® up to 50 tons

toolOpener® up to 50 tons

tO 50.0-HS: Stationary tool handling facility to mount stamping and forming tools up to 2.500 x 3.100 x 950 cm and a weight of 50 tons

[su_expand more_text=”more Information” less_text=”close” height=”0″ text_color=”#0f3060″ link_color=”#fff” more_icon=”icon: cogs” less_icon=”icon: cogs” class=”MehrLesenSm”]The extraction levels of tool parts (upper and lower parts) are identical to assure the loading process via tool changeover carriage. Of course loading and unloading per crane is possible as well. To facilitate the opening of tools with precision sliding guides in connection with higher mould weights without getting things stuck, the precision guided lifting boxes are hydraulically engined under postion control.

Safety pegs ensure automotive standards.

- Control and visualization through Siemens Touch-Panel

- Security-related functions (Buhl-lockings) via PnozMulti-controls (Fa. Pilz)

- Saving the relevant tool information (height of the upper part of the tools mounting position) to approach the lifting position automatically

- Operating modes: Manual, automatic, step-work – Inclusion of the whole machine control system possible

- Buhl-safety pegs for vertical and rotating motion:

For the possibility to lock in every position, 2 x 2 safety-pegs are provided for vertical movements gripping into an oblong hole ridge of both lifting boxes - For rotating movements two safety-pegs are provided, that are able to lock in evey position through a rotating shaft-connected oblong hole disk.

- The pegs lock at emergency shutdown, failure in the power supply, control system shutdown and opened safety door.

- Security fence with four safety doors implemented. Safety control “PnozMulti”.