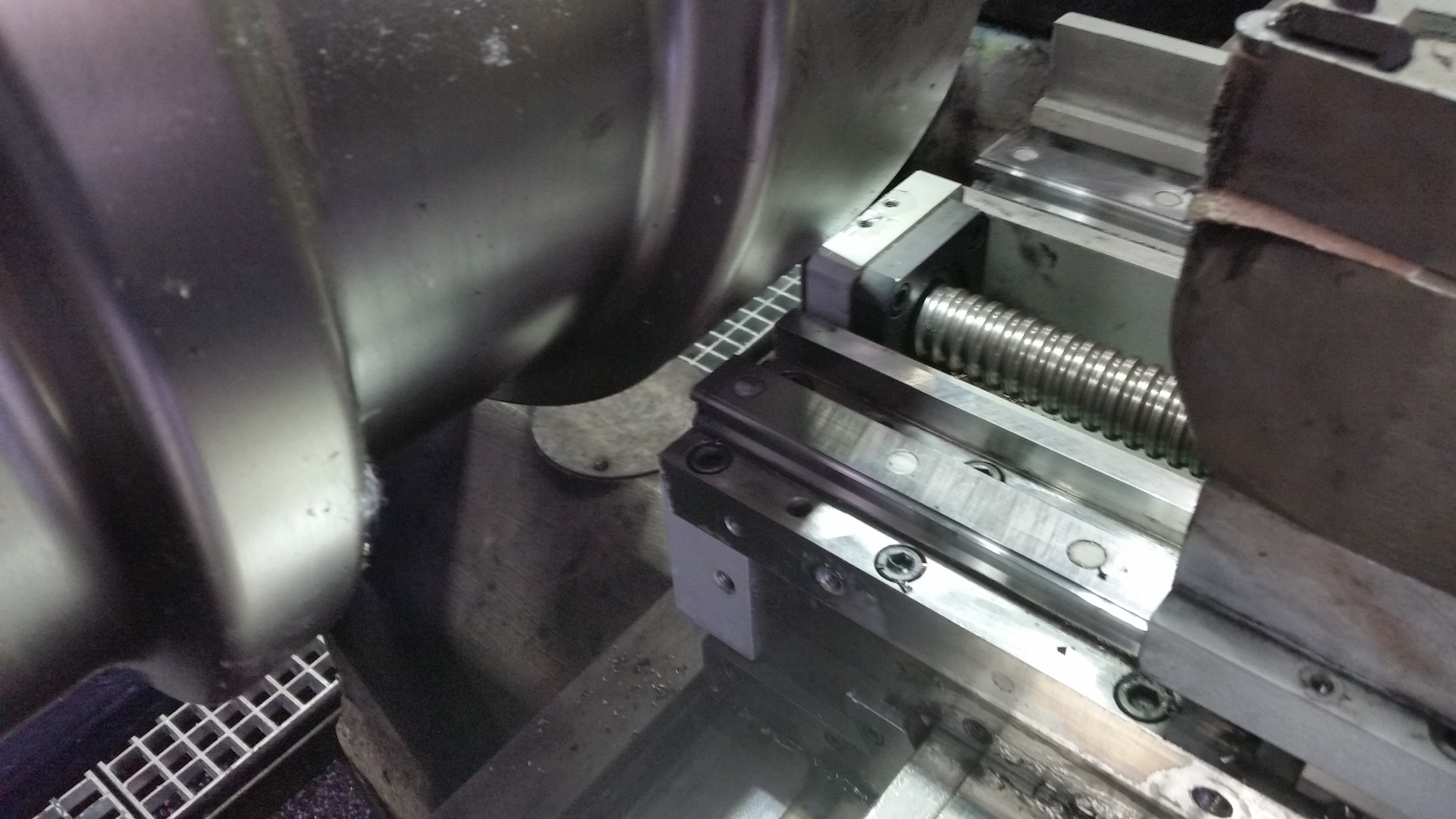

Reconstruction of a Roll Lathe Supporter

Highest precision in the harsh rolling mill environment.

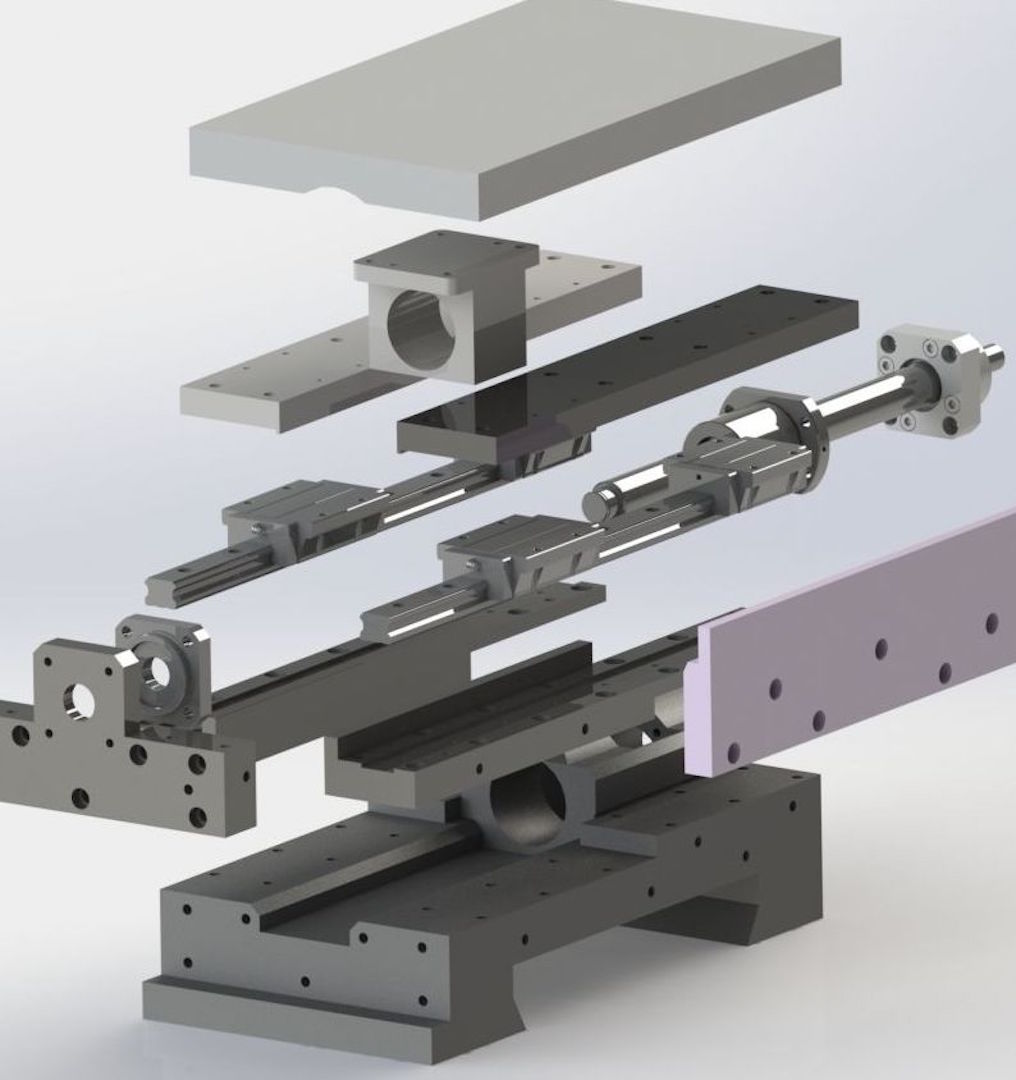

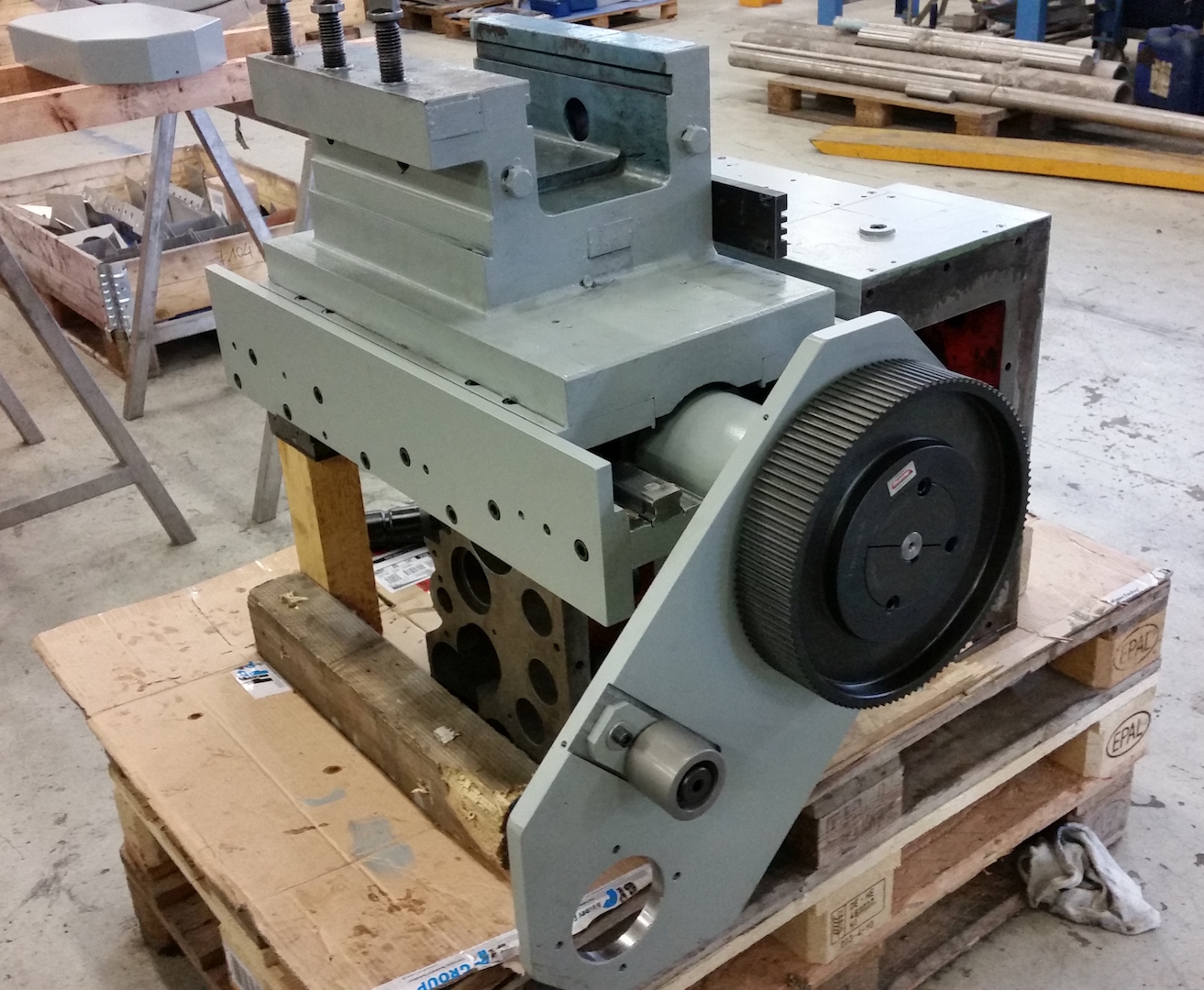

Starting situation: Cast and carbide rollers are processed on the roll lathe “Herkules WDK400”, the cuts are mostly severely interrupted – the roller hardness is up to 80SHC.

The old guiding respectively drive elements were worn or defective. The processed surfaces did not fulfill the quality requirements anymore. The operational safety was no longer ensured.

ASSIGNMENT

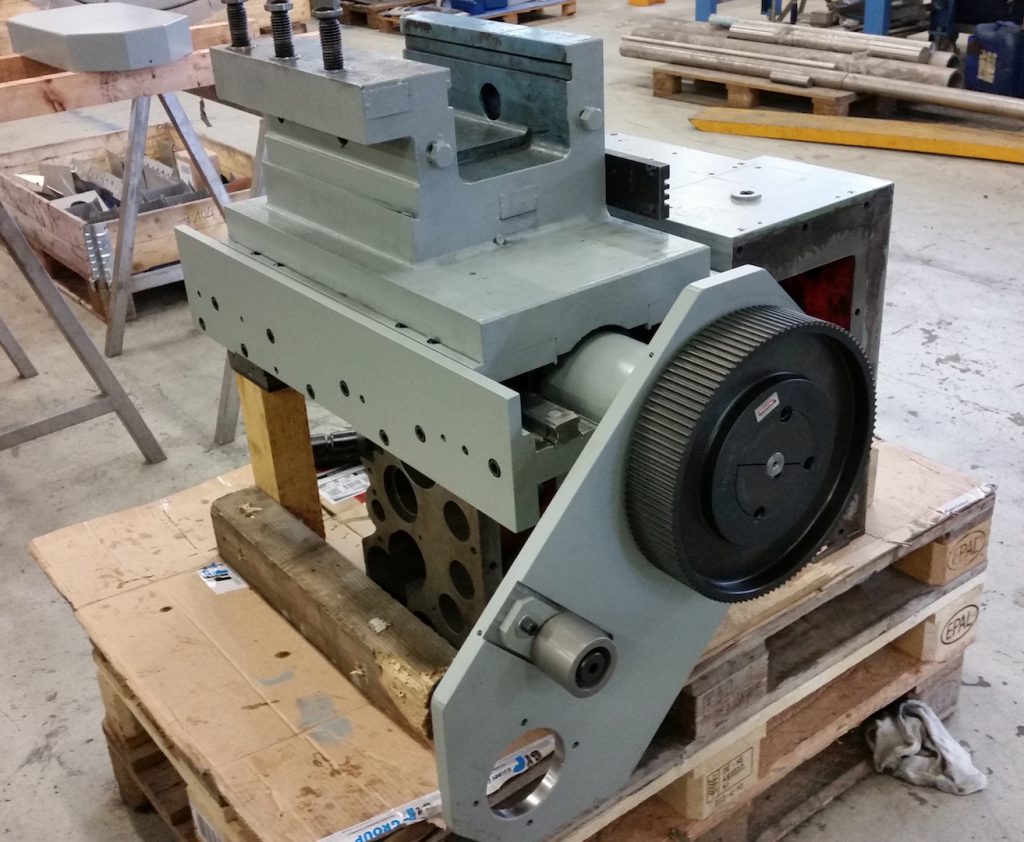

- Development, engineering and construction of a guiding and drive concept, considering the extremely high strains, the required processing quality and operational safety, as well at crash situations.

EXECUTION:

- Digitalizing the machine sector

- Concept development and assessment via simulation and calculation (FEM). Assessment of worst case scenarios

- Construction

- Processing the machine elements and assembling the components

- Adjustment and implementing